PCB Materials Choosing the appropriate printed circuit board material is crucial in today's world of…

A GUIDE ON USING THE RIGHT FR-4 MATERIAL FOR YOUR PROJECT

What Is FR-4 Material?

The flame-Retardant fiberglass-reinforced epoxy compound is known as FR4 material by the NEMA (National Electrical Manufacturers Association). When soldering, your circuit board is shielded by this substance from other elements and heat. A layer of FR4 will typically be sandwiched between two thin layers of copper laminate on an FR4 PCB. Keep in mind that FR4 is a classification given by NEMA rather than a material. But it’s frequently referred to as a substance.

The substance commonly referred to as FR4 material is made of composite materials. Fiberglass that has been woven into a thin, cloth-like sheet forms the material’s base layer. FR4 receives essential structural stability from fiberglass. A flame-resistant epoxy resin is then used to encircle and bind this innermost fiberglass layer. Along with its other physical characteristics,

- This resin is what gives the material its stiffness. Electrical engineers and designers adore FR4 sheets as a base material for PCBs.

- This popularity can be attributed to the material’s affordability, adaptability, and wide range of advantageous physical qualities. Electrical insulators with high dielectric strength are FR4 sheets.

- They are also low in weight, moisture resistant, and have a good strength-to-weight ratio.

How is FR-4 Material Used in PCBs?

FR4 is the perfect default substrate material for high-quality PCB manufacturing operations because of these characteristics. These characteristics can also serve as the basis for PCBs that are both high-quality and affordable when applied properly.

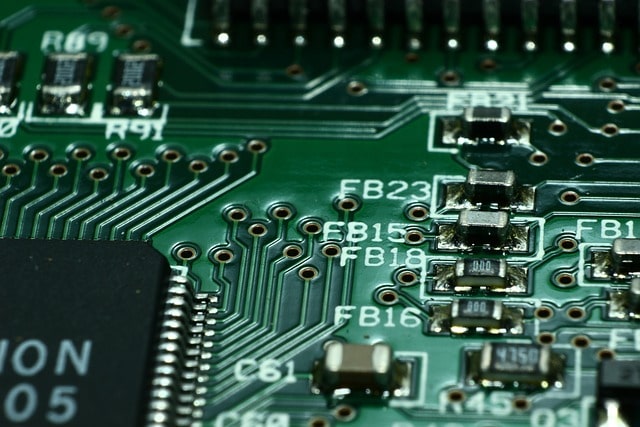

FR4 material serves as the main insulating backbone of a PCB. This serves as the foundation upon which the circuit is built by the manufacturer. The FR4 board is prepared and then heated and laminated with one or more layers of copper foil using adhesive. Depending on the board’s design, this copper may cover one or both sides and create the circuits in the finished result.

To create more complex circuitry, complex PCBs may layer the circuit board or use more than one side. From here, the board is prepared for the final silkscreen layer and the subsequent soldering process by having the circuits designed and etched out before being covered with a solder mask layer.

How To Select FR-4 Material Thickness?

The designer or electrical engineer must specify the FR4 thickness when placing an order for a laminate board for a PCB project. Depending on which is most suitable for the environment, this is measured in inch-based units, such as the thousandth of an inch, thou, or millimeters. FR4 sheets can be any thickness, however, they often range from ten thou to three inches depending on the project’s requirements.

Although board thickness might not appear to be a crucial element in a PCB’s design. To determine the thickness of a board for the design, numerous criteria are considered because board thickness impacts a number of the board’s functional characteristics.

Let’s sum up

We can manage your projects and requirements effectively thanks to our skilled PCB material management team and cutting-edge material management system. We have the means at our disposal to track down the components and supplies you require to cut out the wait and get the job done swiftly.