What Is FR-4 Material? The flame-Retardant fiberglass-reinforced epoxy compound is known as FR4 material by…

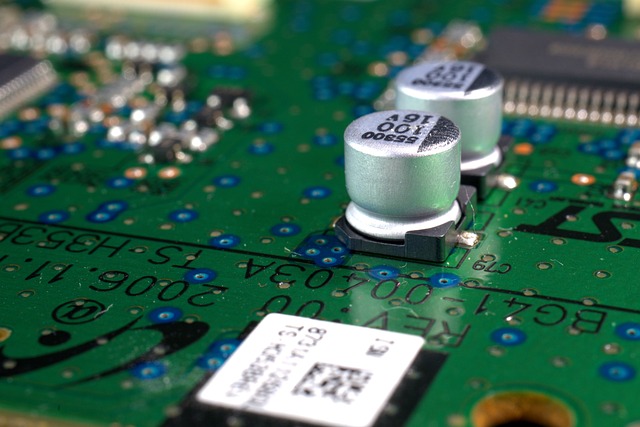

PCB Materials – Most Commonly Used Materials in PCB Manufacturing

PCB Materials

Choosing the appropriate printed circuit board material is crucial in today’s world of sophisticated electronics, cutting-edge technology, downsizing, and ever-increasing signal speed.

The suitable high-quality materials will produce a circuit board that not only performs but adequately lasts for the anticipated lifespan of the product.

As per the design requirements, you can choose from a wide range of board materials starting from FR-4 to Teflon.

Types of PCB materials:

Several types of board materials make them special to use in specific electronic devices.

Below are the most popular materials considered by the designers.

FR4: This substance is a flame-retardant laminate that meets National Electrical Manufacturers Association standards and has an epoxy resin binder and woven-glass fabric layer underneath. FR4 is a widely used material in standard boards due to its excellent specs.

Specifications of FR-4:

- The operating temperature is (50°C to 115°C)

- Outstanding electrical and insulating properties

- Cost friendly

- Low moisture absorption

- High tensile strength

PTFE (Teflon): Teflon is frequently utilized in satellite dishes, high-speed communications systems, and radar applications. Compared to FR4 and other resin materials, it can survive the environment better. Due to its exceptional flexibility, PTFE is indispensable in applications requiring precise tolerances. Additionally, it may be employed in various industries because of how light it is. Additionally, it is resistant to flames, potent physically, stable at all temperatures, and adaptable in use.

Metal: PCBs continue to employ conventional materials like copper, aluminium, iron, etc. Surface Mount Technology can integrate components with these materials. They also offer mechanical toughness. As a result, metal base PCBs have a substantially longer functional life.

Several benefits and drawbacks exist to the various materials used in PCB design and production. The material is selected based on the application, the desired outcome, environmental considerations, and any additional constraints the PCB would experience. Depending on the anticipated results, you should select the PCB material.

Consult the professionals before creating your PCB.

The inappropriate materials can significantly slow down your PCB project or hurt your budget, so speaking with experts is crucial. From the very beginning of every project, PCB Company UK highly qualified experts collaborate with clients to offer recommendations on materials, stacks, and design for manufacturability. Because of our knowledge of cutting-edge material kinds and combinations, we can provide our customers with a practical solution to any design problem.